How to Use a PDR Blending Hammer in Paintless Dent Repair

Share

When it comes to paintless dent repair (PDR), one of the most crucial skills a technician must master is blending. This technique can reduce the edges of a dent, making it nearly invisible to the naked eye. This can save you a large amount of time on your repairs once you get the technique down. One of the essential tools in a PDR technician's arsenal for this process is the PDR blending hammer. In this blog post, we’ll walk you through what a blending hammer is, how to use it, and why it’s indispensable for high-quality PDR.

What is a PDR Blending Hammer?

A PDR blending hammer is a specialized tool designed to smooth and blend the metal around a dent after it has been repaired. The hammer is used for precise tapping on the area surrounding the repaired dent to bring it down to the level of the surrounding metal, ensuring there’s no visible trace of the dent and that the panel has a smooth, factory-like finish. Unlike traditional hammers, PDR blending hammers are generally lighter and feature a threaded area that you can use to add a variety of knockdown tips onto the hammer. A good blending hammer will have an even weight distribution, generally heavier at the head, so that you can stay comfortable while retaining the hammers' ability to move metal efficiently.

A blending hammer typically features a soft tip that prevents the tool from leaving marks on the surface, unlike regular hammers that can dent the panel further. Our 3D Combo Knockdown Tips work very well for blending rails and other high-tension panels on a vehicle. The design of a blending hammer is lightweight yet sturdy enough for gentle, controlled tapping, which helps technicians carefully lower the surrounding edges of the metal to achieve a flawless blend.

Why is a PDR Blending Hammer Important?

In paintless dent repair, the goal is to restore the vehicle's original condition without needing to repaint the damaged area. While you can always use PDR tools like rods, picks, or techniques such as glue pulling to remove the dent, sometimes it can be quicker or more efficient to utilize a technique such as blending. When you blend a ding or dent you are actually increasing the size of the dent. You can do this by lowering the edges of the dent until it is nearly invisible to the naked eye.

A PDR blending hammer helps you accomplish the following:

- Smooth out the panel: It’s used to tap gently around the edges of the dent after the main repair, ensuring that no high spots or low spots remain.

- Prevent overworking the metal: With a blending hammer, you can ensure that you don’t stretch the metal or cause any new issues by using excessive force.

- Restore the factory finish: The controlled use of a blending hammer makes sure that the body panel maintains a smooth, even surface and doesn’t have any noticeable imperfections after the repair.

- Save time: By achieving a smoother result in less time, you can reduce the need for additional steps, making the overall repair process more efficient.

How to Use a PDR Blending Hammer for Dent Repair

Using a blending hammer effectively takes practice and precision. Here’s a step-by-step guide on how to use the blending technique in paintless dent repair:

1. Inspect the Repair Area

Before you begin blending, carefully inspect the dent and the surrounding area. Make sure that the dent is a good candidate for blending. The dent should be rather shallow and not have any severe edges. The metal around the repair should also be in good shape, with no cracks or chips in the paint.

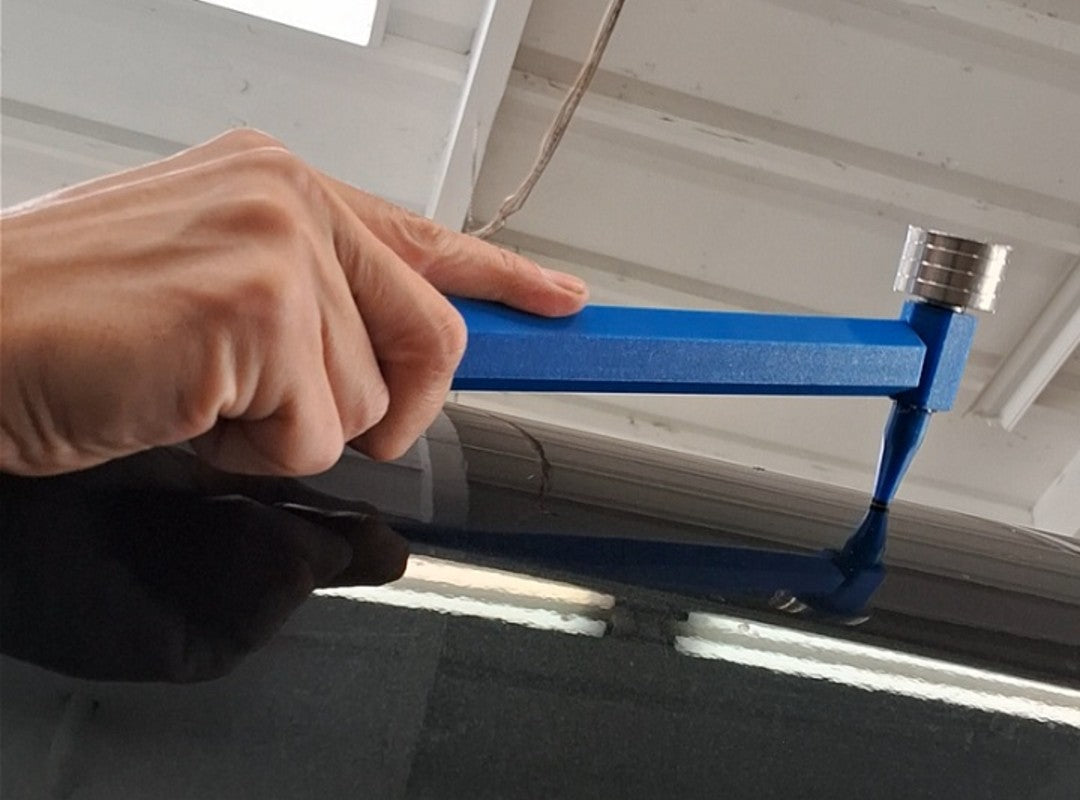

2. Position the Blending Hammer

Hold the PDR blending hammer in a comfortable position and ensure you are standing at an angle where you can work the repair area without applying unnecessary pressure. The soft rubber or plastic tip of the hammer should face the surface you’re working on.

3. Use Gentle Taps

The key to using a blending hammer is to apply gentle, controlled taps around the edges of the dent. Start by tapping lightly around the edges and work your way outward. Avoid using too much force — the goal is to smooth the metal, not to reshape it.

4. Move Around the Area

Work around the entire dent area, using a consistent tapping motion. It’s crucial not to focus too much on one spot, as this could lead to uneven blending. Tap just a little bit harder on the outside edges of the dent, then use lighter taps as you move outward. Make sure that all of your taps are manipulating the metal, otherwise you are losing efficiency. Ensure the metal is being worked evenly to create a smooth finish.

5. Check Your Progress

After a few taps, take a moment to check your progress. Use a reflection to check the surface for any high spots or areas that need more attention. It is always recommended that you use a Paintless Dent Repair Light to examine the panel for any unevenness.

6. Fine-Tune the Finish

Once the dent is blended and smooth, check the area from multiple angles. You might have missed an area that needs attention. Take your PDR light and move it to the other side of the repair, a technique known as cross checking. You can also remove the suction cup from the car and hold the LED portion of the light. Hold your light at arms-length and sweep it over the repaired area. Look for any highs or lows that remain.

Choosing the Right PDR Blending Hammer

When selecting a PDR blending hammer, it’s essential to choose one that’s well-suited to your needs. Here are some key features to look for:

- Handle Material: Most PDR blending hammers come with lightweight aluminum or fiberglass handles, which provide a good balance of strength and comfort. We offer a Blending Hammer with a tilted head, giving you more control while blending because you can rest your wrist on the panel comfortably.

- Hammer Tip: The hammer tip should be soft but durable. Look for hammers with tips made from high-quality plastic, rubber, or Delrin. These materials will allow you to blend the metal without leaving any marks.

- Weight: The weight of the hammer should be comfortable enough to use for long periods but not too heavy that it makes the work difficult. A balanced hammer is ideal.

- Length: A shorter hammer handle gives you better control, while a longer handle will allow you to stand further from the dent. Try multiple blending hammers to find what works best for you.

Conclusion

A PDR blending hammer is an indispensable tool for any professional paintless dent repair technician. By using this tool, you can ensure that the repaired area blends seamlessly with the rest of the car's body, providing a flawless finish that looks as good as new. Whether you're fixing a small door ding or a larger bumper dent, mastering the use of a PDR blending hammer will elevate your repair skills and help you deliver high-quality, reliable results.

If you're serious about getting into paintless dent repair, having the right tools, including a quality PDR blending hammer, is essential. With the right technique, the blending hammer allows you to fine-tune your repairs and speed up the dent repair process. It can create a smooth, invisible fix that leaves your customers satisfied every time.